Events Used

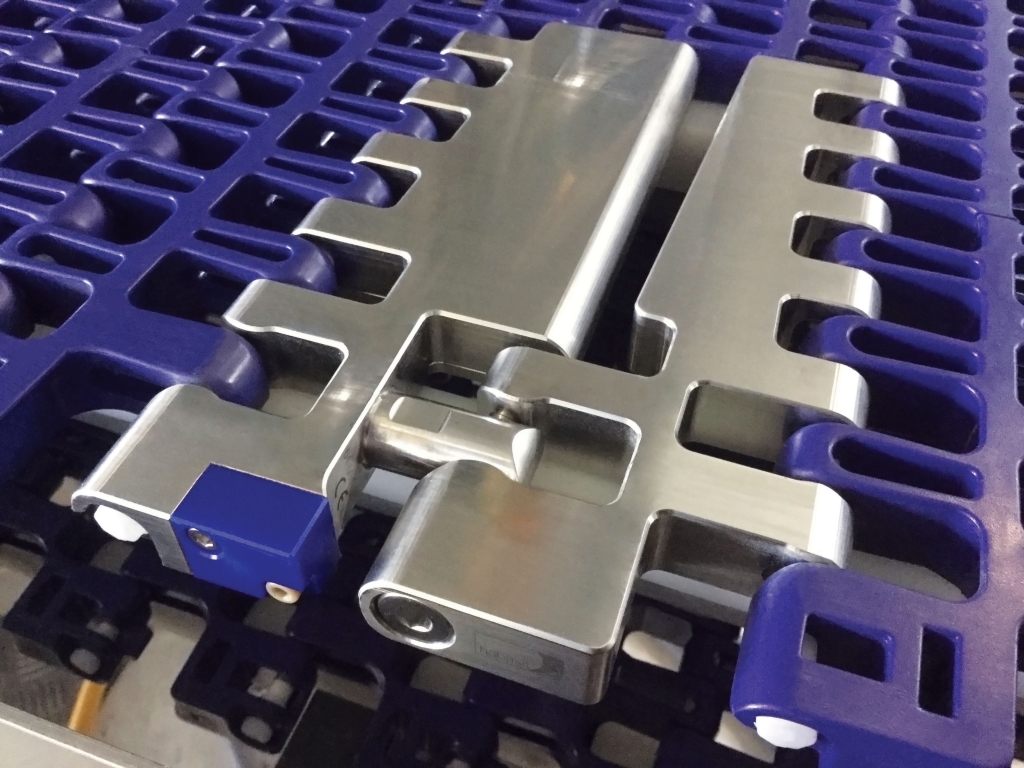

The sensor inside a conveyor belt

~ Achieving elegance from novel engineering challenges ~

Elegant engineering is all around us. The Face ID in your phone, the keyless go in your car, the smart speaker in your home; these devices make our lives perceptibly easier. What’s not always easy are the novel design challenges engineers must overcome to realise these products. When Habasit, a leading provider of conveyor and power transmission systems, hatched an ambitious plan to create an embedded wireless force-sensing link in one of its curved plastic modular belt conveyor systems, it worked with Mantracourt to achieve elegance.

In 2018, Andrew Richardson was working as a project manager in the plastics R&D department at Habasit, a leading global manufacturer of conveyor and power transmission systems, based in Reinach, Switzerland. A large customer in the food and beverage industry had recently come to Habasit with a query; it wanted to measure tension in the spiral conveyor belt system on its bread production line.

After the bread came out of the oven, it made its way through the rising spiral conveyors to allow it to cool before being packaged. Reminiscent of the holding pattern sometimes used by passenger aircraft on the approach to an airport, the spiral conveyors are a common sight in many food production environments. They offer a space saving way of increasing production throughput and are also used to move products up and down between different levels in the plant, sometimes reaching a height of two storeys.

However, because the belt in a spiral conveyor needs to follow a curved path, as well as a straight path, one of the biggest challenges these types of conveyors face is tension. High levels of tension in the belt can cause it to buckle and/or break.

In the food industry in particular, this problem is exacerbated by food particles from the likes of bread and pastries becoming lodged in the gaps between the plastic links. Between cleaning cycles, this leads to an increase in friction, which leads to higher belt tension.

“In the industry today, it’s common for engineers to measure the condition of motors and pumps,” explains Richardson. “However, it’s less common to measure the force inside the conveyor belt itself. It’s a very challenging environment, with ovens and chillers working in close proximity to make everything from frozen pizza to cooked chicken.”

Using sensors in this environment is not easy. The traditional approach involves a maintenance engineer visiting the site to carry out repairs and upgrades. During these visits, the engineer will also check tension using a load-cell that clips onto the surface of the belt and measures the force between the modular links. However, this approach has its limitations.

“The downside with this method is that it only takes place periodically as part of the scheduled maintenance visits and means stopping the conveyor,” explains Richardson. “Secondly, the load cell that measures tension only works on some parts of the conveyor system and can’t fit through tight spaces, so you only really get a limited picture of belt tension in the system.”

The team at Habasit came up with an ambitious plan to create a sensor that would fit inside a metal link that was the same shape and size as one of the existing plastic modular links in the belt. This special link would continuously transmit data wirelessly back to a base station.

“We knew it was not an easy design engineering challenge,” says Richardson. “All of the electronics had to fit inside the small envelope occupied by the link, including the sensor, the circuit board, the battery and the antenna. The components had to be durable enough to withstand extreme temperature changes and the wireless transmission had to reliably relay data through the complex plant environment.”

Habasit reached out to partner with a specialist to support the development of the link, but initially struggled. “The relationship with the first company we engaged with quickly fell through due to a lack of responsiveness,” says Richardson. “We then reached out to Mantracourt and hit it off immediately. This was before the pandemic, so our team flew out to the UK and spent the day with the team at Mantracourt, to really give them a feel for our needs.”

Exeter-based Mantracourt Electronics designs and manufactures signal conditioning equipment and sensor systems, specialising in miniature high-performance electronics and wireless telemetry systems.

“The link is made up of four areas,” explains Tom Lilly, application engineer at Mantracourt. “At the most basic level, a strain gauge sensor connected to the internal frame of the metal link detects small changes in deformation caused by tension. These signals must be captured, amplified and converted into engineering units using signal conditioning electronics. The data must then be wirelessly transmitted to a base station using an antenna. Finally, the unit needs to be effectively powered by a battery that delivers energy density, long life and a small size.”

With the strain gauge and signal conditioning board in place, the team came up against the first engineering challenge: the battery. The standard cell was sourced from a third-party supplier and was designed for harsh environments. However, it was the battery’s voltage that was the issue.

“We used our standard T24 SAE printed circuit board for this kind of application,” explains Lilly. “Although we customised some circuitry for improved power management specific to Habasit’s requirements.”

The next novel development challenge was the antenna. With all the other components inside the link, there was not much room left for a standard antenna. Habasit reached out to a local company but found that having one developed would have taken a year and considerable cost. Mantracourt recommended a supplier who came in within budget and delivered quickly.

“The antenna uses a 2.4 GHz radio, but the protocol is proprietary, with the language written by Mantracourt,” explains Lilly. “In ideal conditions the range is 800 m, but obviously we don’t have a perfect line of sight in the plant. Our T24 protocol is similar to the Bluetooth Low Energy (BLE) advertising packet in that it continues to broadcast packets of data until it is told to stop. This means much lower overheads.

“Using this approach has another benefit in that the protocol allows monitoring of multiple transmissions between the sensor devices and the base station or other receivers. This gives Habasit the ability to monitor one-to-one, one-to-many, many-to-one and many-to-many devices. This means a single operator can use one device to monitor a single link, or multiple operators can use multiple devices to monitor multiple links.”

To add to this, Mantracourt’s T24 wireless telemetry system can link to SensorSpace. This is a cloud-based platform that allows users to remotely monitor the live feed. This data can be stored, graphed and trended using dashboards — and further types of sensors, from pressure and temperature, can be added to understand what’s going on across the process.

“The result of the project is that we’ve now launched the sensor,” explains Richardson. “It’s called the Habasit Spiral Smart Link and is designed as an embedded system to monitor belt tension. It allows users to perform non-stop diagnostics, prevent sudden downtime and accurately schedule preventative maintenance for cleaning and sanitation.

“The device has been in place with our original customer for nearly two years and they’ve already been able to increase belt lifetime, reduce downtime and ultimately reduce their total cost of ownership. We can also remotely monitor the condition of the belt 24/7, support with on-site assistance where necessary and the customer receives direct push notifications via email and SMS.

“We’re really pleased with our collaboration with Mantracourt. The team were really easy to work with and their expertise shone through in the final product. We’ve already placed more orders for components and as our customers begin to roll out the product across the world, there will be opportunity to develop the product and add features. What stands out for me is that we realised an ambitious plan that’s delivered an elegant solution.”

To find out more about the Habasit Spiral Smart Link visit www.habasit.com. To find out more about Mantracourt’s T24 telemetry system , visit www.mantracourt.com.